ERP and PLM systems are complementary systems that can communicate with one another while serving different business requirements.

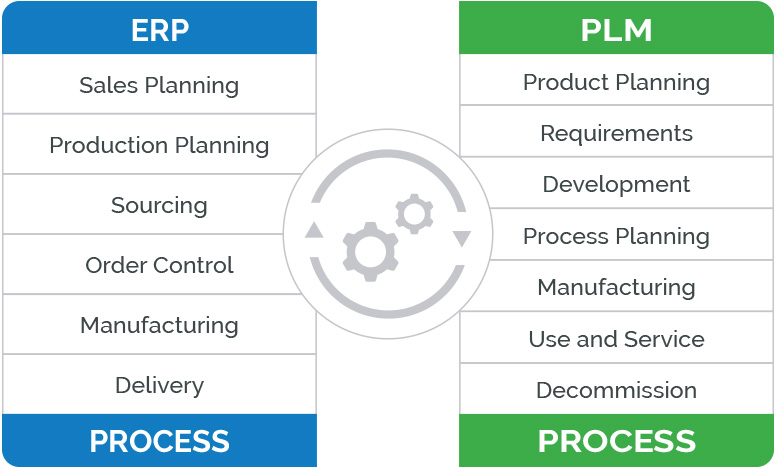

ERP and PLM systems are complementary systems that can communicate with one another while serving different business requirements. Because PLM is designed to manage product development information and processes and ERP is designed to manage production resource planning, it makes financial sense to employ these systems in that order. Product information should be housed in a PLM solution to process, manage, and communicate.

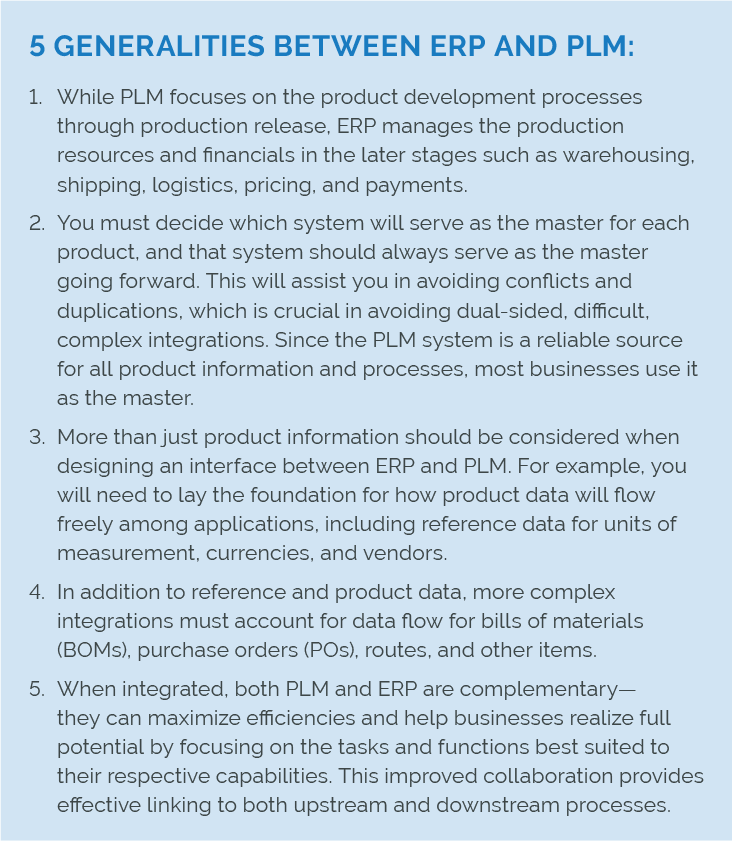

An ERP solution that interfaces with the existing PLM solution is useful once the product design has progressed to the stage when resources must be controlled to produce the design. By connecting ERP and PLM, engineering teams can make better design decisions by gaining visibility into information like component costs and lead times while manufacturing can access the most current product data anytime and share it with the necessary departments to ensure precise financial planning.

Proper coordination, synchronization, and integration of ERP and PLM solutions can bring value by boosting efficiency, collaboration, and data integrity across design and manufacturing. Integration ensures that everyone in the organization is working with the most current product information at all phases of the product lifecycle. You can optimize essential upstream and downstream processes and ensure continual cost, quality, and product improvements by sharing information between your ERP and PLM systems.

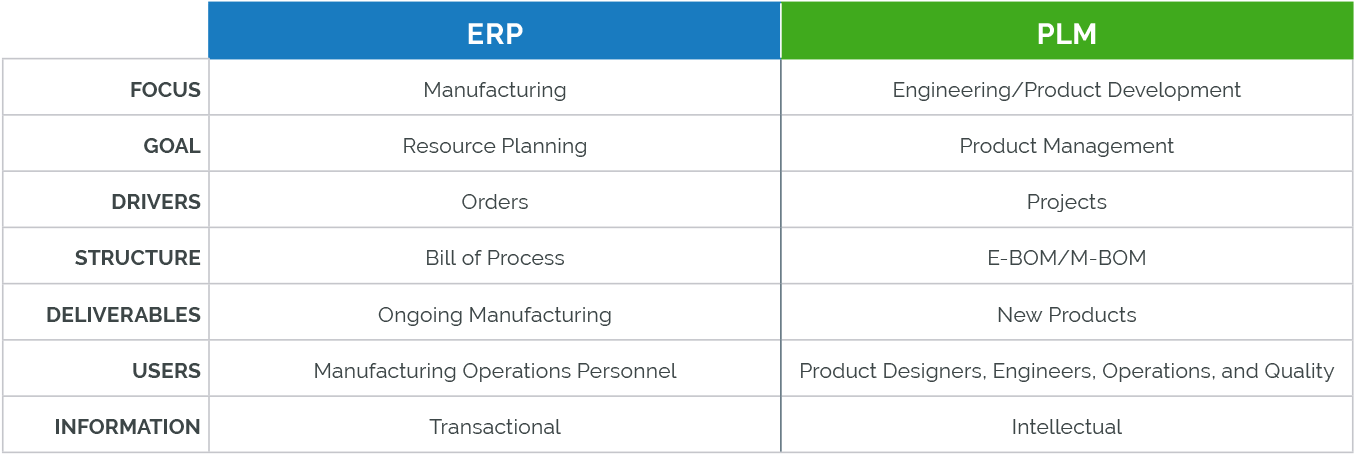

ERP and PLM are essential components of a system landscape for manufacturing companies. It’s crucial to comprehend their individual capabilities and use cases to maximize their benefits.

ERP and PLM integration enables collaboration by having complementary functionalities for design and manufacturing processes. Design, development, sampling, approval, and other crucial processes for producing competitive products are carried out and approved in the PLM system. Once the products are released, ERP manages the sourcing, operations, finances, and sales.

When your PLM and ERP systems are not integrated, multiple staff are responsible for manually entering and re-entering data and information between the two systems (and fixing errors that inevitably occur during such processes). The processes of updating and transferring information are completely automated when ERP and PLM systems are integrated, removing the risk of manual entry and allowing your staff to focus on more business-critical duties. Also, automation entails near-real-time data transfer, so everyone is current on the present situation and has access to actionable operations-related information.

ERP and PLM integration means that all departments have access to and are working from the same information. Global companies will profit the most from this, as clear communication across many departments is critical for commercial success—subject matter experts (SMEs) will benefit as well (especially if teams are working remotely). Without integration, various departments typically do not have access to one another’s data—or separate systems use incompatible formats—resulting in communication challenges, mistakes, inefficiencies, extra expenditures, and income loss. Integrating ERP with PLM provides everyone with automatically updated information, promoting communication and collaboration between departments and resulting in improved alignment, performance, and productivity.

ERP and PLM integration improves efficiency, which results in immediate cost savings for the company. Because data is transferred automatically between systems, manual intervention is reduced. This supports better resource allocation by eliminating duplicate data entries. This also improves accuracy and guarantees that the two systems are synchronized. Visibility into information in ERP allows engineers to make better design decisions based on cost, lead time, and availability. This improved precision allows businesses to avoid supply shortages that can cause delays in order fulfillment and increase supply chain expenses; it can also help them save money by not carrying excess goods. Additionally, giving manufacturing the latest and most accurate design information ensures they are using the correct version and can save them from costly late-stage scrap and rework. Having all your information visible across design and manufacturing provides an accurate picture of company operations. This allows you to identify areas for business improvement and cost-cutting potential.

The greater productivity, improved collaboration, and error reduction allowed by ERP and PLM integration result in happier, more satisfied customers since you can fulfill their orders faster and more accurately. It also means that as your operations become more automated, your staff will be able to focus more on order fulfillment, customer service, and product enhancement. With better access to company-wide data, you can pay greater attention to pricing strategies, allowing you to make competitive modifications to grow your customer base.

ERP or PLM, Which Comes First?

ERP or PLM, Which Comes First?Manufacturers who start with an ERP solution and then add PLM later encounter several issues when it comes to effectively managing product records. Without a PLM solution to centralize designs and manage revisions, an engineering team, for example, can risk delivering the wrong product information to an ERP solution. Companies can avoid incorrect part ordering and inefficient spending by managing product documentation and revision changes in PLM and then synchronizing final product data to an ERP solution. Other concerns that can develop if product information is not first controlled in PLM can include product recalls and violations of compliance rules. When a firm adopts PLM after an ERP solution is already up and running, synchronizing data and establishing a data connection may be more difficult. The time and money spent determining whether product data should be migrated from an ERP to a PLM solution would be better spent elsewhere in the manufacturing process. A company can benefit from a more coherent and efficient manufacturing process with fewer oversights by storing product information in PLM and subsequently feeding it to an ERP solution.