The green revolution is here and is helping to create environmentally friendly products that are improving how we live, work, and play. For electric transportation companies, this means meeting increased consumer demand and net-zero targets for carbon-neutral transportation if they want to win the race.

Electric vehicle (EV) manufacturers and their supply chain partners are more dispersed than ever before. Everyone involved in new product development and introduction needs easy access to the latest product and quality information to ensure products can be brought to market ahead of the competition.

Whether you have a few partners, or hundreds, you need a platform designed for secure, rapid collaboration and traceability from early design through volume production.

Read our brief to learn how collaborative supply chains are driving in a new era of innovation.

Whether it be an extended driving range, a reduced charging time, or a new driver assist capability—electric transportation manufacturers must address the ever-increasing demands of today’s consumer.

To create a more connected customer experience and stand out from the competition, manufacturers are leveraging complex technologies like the Internet of Things (IoT), sensors, artificial intelligence (AI), and augmented reality (AR) for the development of smarter, more sophisticated products.

By combining mechanical, electrical, software, and firmware designs into a single, unified system, Arena ensures their interoperability and enables manufacturers to manage increasing product complexity, while driving continuous innovation.

Read this report to gather insights on how you can advance your products to meet the evolving needs of customers in today’s fast-paced environment.

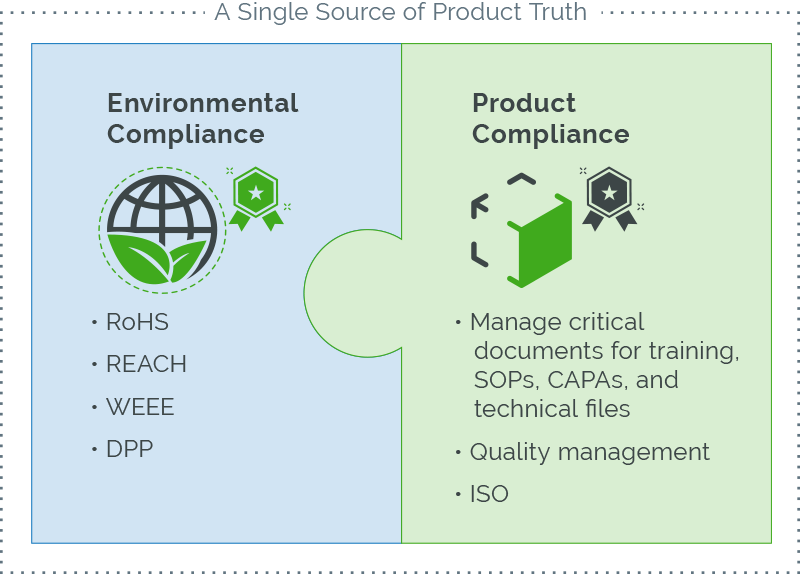

E-transportation manufacturers are subject to stringent and constantly evolving product and environmental regulations.

To ensure compliance, manufacturers need to continually monitor the environmental impact of their products throughout the entire lifecycle—from sourcing of raw materials and production to the reuse or recycling of certain components as they reach their end of life.

Arena makes it easy to manage components and material compliance evidence for RoHS, REACH, WEEE, DPP, and other global regulations with seamless integrations to electronic component databases like Octopart and SiliconExpert.

Supply chain disruptions can prevent manufacturers from sourcing critical parts and materials from across the globe, resulting in product delays and decreased revenue.

To cross the finish line first, global manufacturers need to continually prepare for supply chain disruptions. This process is now largely driven by digital transformation technologies which provide companies with new powerful solutions for enabling deep collaborative relationships between internal teams and supply chain partners.

Listen to this Global Auto Industry podcast to hear insights on how to navigate supply chain and product development obstacles.

To overcome complex manufacturing, compliance and collaboration challenges, it’s crucial to align digital transformation efforts with business value.

Identifying the most pressing problems impacting financial and operational goals – and measuring the value attainable from resolving them – provides a solid foundation for digital transformation

Read this report to understand how global manufacturers are progressing with digital transformation (DX) and how these digital projects are transforming physical processes across the value chain for significant financial gains.

Many EV manufacturers are adopting cloud-based product lifecycle management (PLM) software solutions to gain a single source of product truth, speed global collaboration between internal teams and external partners, and meet environmental compliance regulations.

Don’t put the brakes on implementing a Cloud PLM solution. Check out this blog post to see how easy it is to migrate to the Cloud.

Electric vehicle (EV) manufacturers and their supply chain partners are more dispersed than ever before. Everyone involved in new product development and introduction needs easy access to the latest product and quality information to ensure products can be brought to market ahead of the competition.

Whether you have a few partners, or hundreds, you need a platform designed for secure, rapid collaboration and traceability from early design through volume production.

Read our brief to learn how collaborative supply chains are driving in a new era of innovation.

Whether it be an extended driving range, a reduced charging time, or a new driver assist capability—electric transportation manufacturers must address the ever-increasing demands of today’s consumer.

To create a more connected customer experience and stand out from the competition, manufacturers are leveraging complex technologies like the Internet of Things (IoT), sensors, artificial intelligence (AI), and augmented reality (AR) for the development of smarter, more sophisticated products.

By combining mechanical, electrical, software, and firmware designs into a single, unified system, Arena ensures their interoperability and enables manufacturers to manage increasing product complexity, while driving continuous innovation.

Read this report to gather insights on how you can advance your products to meet the evolving needs of customers in today’s fast-paced environment.

E-transportation manufacturers are subject to stringent and constantly evolving product and environmental regulations.

To ensure compliance, manufacturers need to continually monitor the environmental impact of their products throughout the entire lifecycle—from sourcing of raw materials and production to the reuse or recycling of certain components as they reach their end of life.

Arena makes it easy to manage components and material compliance evidence for RoHS, REACH, WEEE and other regulations with seamless integrations to electronic component databases like Octopart and SiliconExpert.

Supply chain disruptions can prevent manufacturers from sourcing critical parts and materials from across the globe, resulting in product delays and decreased revenue.

To cross the finish line first, global manufacturers need to continually prepare for supply chain disruptions. This process is now largely driven by digital transformation technologies which provide companies with new powerful solutions for enabling deep collaborative relationships between internal teams and supply chain partners.

Listen to this Global Auto Industry podcast to hear insights on how to navigate supply chain and product development obstacles.

To overcome complex manufacturing, compliance and collaboration challenges, it’s crucial to align digital transformation efforts with business value.

Identifying the most pressing problems impacting financial and operational goals – and measuring the value attainable from resolving them – provides a solid foundation for digital transformation

Read this report to understand how global manufacturers are progressing with digital transformation (DX) and how these digital projects are transforming physical processes across the value chain for significant financial gains.

Many EV manufacturers are adopting cloud-based product lifecycle management (PLM) software solutions to gain a single source of product truth, speed global collaboration between internal teams and external partners, and meet environmental compliance regulations.

Don’t put the brakes on implementing a Cloud PLM solution. Check out this blog post to see how easy it is to migrate to the Cloud.

“When it comes to PLM solutions, Arena is better than any system I have used in the past. The value Arena provides compared to other commercial systems is remarkable. And because it is cloud-based, we have a system that can scale as our needs change and our business grows. We know that Arena PLM can take us through the next two generations of our evolution.”

—Mark Hanna, Vice President of Operations, FreeWire Technologies

Check out these resources to learn how you can win the electric vehicle race.

Blog Posts

How Digital Transformation Helps EV Companies Accelerate Product Innovation

Regulatory Compliance Essentials for EV Manufacturers

How EV Manufacturers Can Navigate Supply Chain Complexity

Honk, if You’re Driving Green This Earth Day

Overcoming Product Development Challenges in EV Manufacturing

Ebooks and Infographics

Get Your Compliant Products To Market Faster with Arena PLM