Improving the time to Release Products: Speeding Time to Market (TTM)

What is Time to market and why you should care

While the definition of time to market (TTM) can vary depending on the company and product complexity, for the purpose of this article we are going to define time to market as the period of time from when a product idea has general agreement and resources are committed to the project, to the time the final product ships to customers.

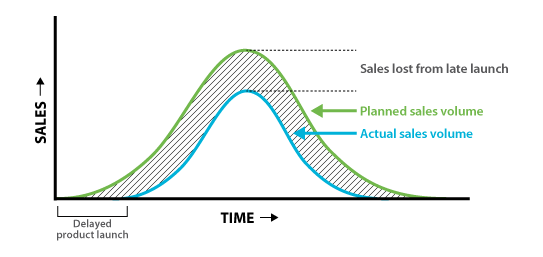

In today’s product development environment, products, and the technologies they’re based on change rapidly, as do the number of competitors for market share. This means that time to market and finding ways of optimizing it are critical components that directly affect revenue. For example, if your product launch is delayed by 6 months, that’s 6 months that your competitor might grab market share, thus reducing any first-mover advantages when you finally get your product launched.

The better control you have over your product development processes, the better you’ll be able to control and predict your time to market and get new technology out while it’s still new.

Total sales volume is reduced from plan due to delayed product launch. Getting back on plan is highly unlikely as a result of increased competition.

Here are some additional reasons companies care about improving their time to market:

- Efficient resource management — Having a reliable timeline will allow you to prepare in advance for transportation times and costs, build schedules based on part lead times and headcount planning to satisfy the needs in various project phases.

- Predictable schedules and launch dates — The product development process is long and complicated. If you can accurately predict when your product will ship, you can take advantage of tradeshows, holiday buying seasons, and other marketing opportunities.

- Increased total revenue — The earlier you get your product to market (without cutting corners or compromising quality) the greater the revenue you can generate because your product faces less competition. In addition, you earn revenue for more of the product lifecycle.

Revision control during product development improves your time to market

If you use paper, spreadsheets, or a shared drive to keep track of revisions—errors and confusion about where the latest revision is stored can create quality issues, launch delays, and expensive rework. Do these conversations sound familiar to you?

“Are you sure Bob put the latest revision up on the drive?”

“I saw your order for the prototype parts yesterday morning, but did you see the updates posted last night?”

“We emailed the new revision last week… Did you check your spam folder?”

“His desk is a mess! No wonder he didn’t see the file with all the changes!”

During the design phase, engineers constantly share information about mechanical, electrical, and software designs. If there isn’t a controlled process, things can easily go haywire. If a mechanical engineer makes a major design change and doesn’t save the new revision on the shared drive, the electrical engineer may design their printed circuit board assembly (PCBA) to fit into an obsolete mechanical chassis layout.

If you rely on email to distribute new revisions, recipients can easily lose track or miss these emails in their cluttered inbox. Either way, if you design the wrong revision, you’ve wasted hours or even days of work and pushed out the deadline for design completion. Issues like this may be small in and of themselves, but there’s never just one thing that goes wrong, so collectively they can add up and destroy your time to market target.

By the time you’re ready to start prototyping, you’ve already begun to source suppliers and to get quotes. While you’re gathering these quotes from vendors and suppliers your product is still changing, so the revisions you got quotes for last week may not be the ones you place orders for this week. When you go to place an order, if your supplier is working off the wrong revision because the email with the drawing of the new revision got eaten by a voracious spam filter, you’re facing some considerable risks. If the parts you ordered don’t fit together, you can’t build your prototype, and ordering new parts means wasting a lot of time and money, especially if you have to pay expedite fees.

Having a strong revision control process helps manage your product development and reduces possibilities for mistakes that can blow your time to market target. If everyone follows the same process and designs are kept in a single, easy-to-access location everyone can get to the right information when they need it.

Controlled changes minimize time to market risk as your product transfers to manufacturing

As you move from new product development (NPD) to new product introduction (NPI), it’s common for the design to continue to evolve based on prototyping and manufacturing feedback. However, procurement teams need to know which components are final and which are still being further evaluated so they can begin to order parts. For components with longer supplier lead times, you may decide to place a partial order so that build timelines won’t be compromised, but not place the full order and risk wasting lots of money on unusable parts.

These critical purchasing decisions require manufacturing to have accurate information in hand, which will only happen with a solid change process in place. Manufacturing teams also need to make decisions about where to build the product. Volume production requires the ability to build a high-quality product with a stable, repeatable process. If components and parts are in flux, you might decide to keep the product build under your internal control for easy monitoring. For example, if your product’s firmware is updated frequently, you might decide to launch the product with final programming and test in-house. Then once the firmware has stabilized, move that step of the manufacturing process out to a contract manufacturer (CM).

Having controlled change processes in place facilitates access to and communication of the latest product information, therefore manufacturing will have more reliable information to base decisions on. Quotes will be more accurate, supplier lead times better managed, and build timelines correctly projected. In addition, when you have a reliable history of product changes including what product information you’ve shared and with whom, it becomes much easier and less time consuming when you need to go back and debug a problem.

Shared information smooths product launch planning and speeds your time to market

It would be nice to believe that once you have your working prototype, your worries cease. However, in order to get your product off the factory floor and into the customer’s hands, there is a bit of ‘logistical spaghetti’ that needs to be sorted out. There are many choices that need to be made regarding packaging, transportation and shipping, warehousing, fulfillment and delivery, and marketing launch activities. What’s more, many of these decisions need to happen way before you transfer your product to manufacturing. Let’s work backward through a timeline of how to get a product from your manufacturer to a store to be ready to sell.

If the product needs to be on store shelves and advertised by a certain date, it needs to arrive at the store’s warehouse before that date. Prior to that, it needs to be shipped from your contract manufacturer to that warehouse via a route that goes through customs. Before you can start shipping you need to understand what transportation method you are going to use and how you can maximize the packaging of your box to ship most cost effectively. In addition, you need to know how much product to ship to the store’s warehouse and if you’ll be capable of meeting that demand.

The most important requirement for these logistical preparations is your ability to accurately predict when your product will be ready to start volume manufacturing. Your ability to your product launch date depends on having controlled product development processes in place that help you stay on track and minimize the chances that something significant throws off your schedule. For example, if your revision or change processes aren’t reliable, you could design parts that don’t fit together or have software and electronics that are not interoperable. Additionally, when you share your product information with your supply chain partners—it may get lost, misplaced, or stuck in a spam folder, resulting in orders for the wrong parts. Either way, these types of errors are expensive and can easily cost you days, weeks, or even months of delays. If the estimation for your time to market launch is wrong, you could end up missing promotional opportunities, paying for empty warehouse space and idle fulfillment staff, or losing difficult-to-get retail shelf space.

Improve your time to market with controlled product development processes

When you launch your product on time, you can beat your competition to the market and enjoy first-mover advantages. Doing so requires controlled product development processes including revision control of components and accelerated change review processes. When your product development process is cloud-enabled, your internal and external suppliers can get products to customers faster and avoid unnecessary risks and costly consequences.

Arena PLM speeds product launches

Arena PLM is a cloud-based solution that brings your entire product record together, including the bill of materials (BOM), and streamlines new product development (NPD) and new product introduction (NPI) processes. Arena gives you a controlled, centralized way to manage your product record anytime and anywhere—making it easy to collaborate with your supply chain partners.