8 Ways PLM Can Support Circularity Concepts for Product Development

On March 2020, the European Commission adopted the new Circular Economy Action plan (CEAP).1 It’s become the foundation of the European Green Deal, Europe’s new agenda for sustainable growth. Companies looking for a more comprehensive industrial transformation toward climate neutrality and long-term viability must include circularity as part of their business model.

Circularity considers a product’s lifecycle and how it may or may not end up as waste at the end of life. Circularity can deliver significant material cost savings through value chains and manufacturing processes, and create additional, value and new business opportunities.

Emerging digital and cloud technologies like big data, cloud computing, artificial intelligence (AI), blockchain, the Internet of Things (IoT), and product lifecycle management (PLM) can benefit the circular economy by addressing a wide range of global issues.

Manufacturers adopting a circular economy are realizing they need to think differently. Reducing waste in production lines is more difficult than expected when transitioning from a linear (extract-make-dispose) business model.

When it comes to circular transition there are no one-size-fits-all solutions. The circular economy requires a significant change in how products are designed, manufactured, consumed, and disposed. Circularity requires coordination among stakeholders across the complete value chain and the use of complex systems thinking.

Adopting a circular product development model

The product lifecycle is becoming more circular, with new business models and service offerings like reselling, repair, refurbishing, or recycling because of longer-lasting product design. By applying circular design and development practices, manufacturers can significantly reduce their environmental impact.

Key Components of a Circular Product Development Model—Process, Lifecycle Extension, and Service:

Process

- Circular value chain: Closing the loop along the full value chain is the goal of production cycles. Using only renewable, recyclable, or biodegradable materials in subsequent lifecycles will reduce costs, improve predictability, and increase control.

- Recovery and collection including industrial collaboration: With an emphasis on production and consumption, everything that was previously regarded as waste is retained for other uses through tracing and recovering products at end of life. Another aspect of this is the reuse of waste and byproducts from the manufacturing process and incentive-based return programs. Both upcycling (into products of greater value) and downcycling (into products of lower value) can be a part of the recycling process.

Lifecycle Extension

- Durability, and modularity with repair services: By maintaining and enhancing products through repair, upgrade, refurbishment, or remarketing, the life of products can be extended with an improved design process that places a focus on design for disassembly, material selection for durability, or design for repair.

- Personalization, made-to-order, and support: A more tailored, long-term customer relationship is desired to close the loops, use the least number of materials/products, recycle them, and reduce resource usage. It provides a clearer understanding of the user’s new business requirements and the possible demand for the product itself.

Service

- Product service system and dematerialized services: The total cost of ownership is assumed by the maker or retailer, forcing attention to be paid to product usability, reusability, durability, longevity, and reliability.

- Collaborative/sharing economy: With the help of digital technology, consumers and businesses can form new connections and take advantage of new possibilities to rent, share, trade, or borrow unused resources.2

Laying the foundation for sustainability success

Companies can benefit from these four broad circular economic action items as part of their environmental, social, and governance (ESG) strategy and efforts. They include near-term stimulus, long-term economic growth, and renewal.

- Set directions and targets: Articulate high-level goals that represent your dedication to a more circular economy and sustainable future. Integrate this agenda with other plans (like an industrial or digital strategy) and track progress using metrics.

- Create enablers and remove barriers: Use resources like product standards, revised regulations, and better transparency to address multiple nonfinancial barriers to the European Union’s (EU) transition to a circular economy.

- Make the economics work: Identify lead markets, level the playing field through trade policy, taxation, or other measures, and stimulate demand through quotas, content, and standards.

- Pursue long-term value: Establish a coherent circular economy policy framework: A significant portion of the circular economy’s potential cannot be triggered by one-time rescue packages or government involvement. A thorough and organized policy framework to address barriers and gradually change the economic case is still extremely relevant for much of the circular economy transition.3

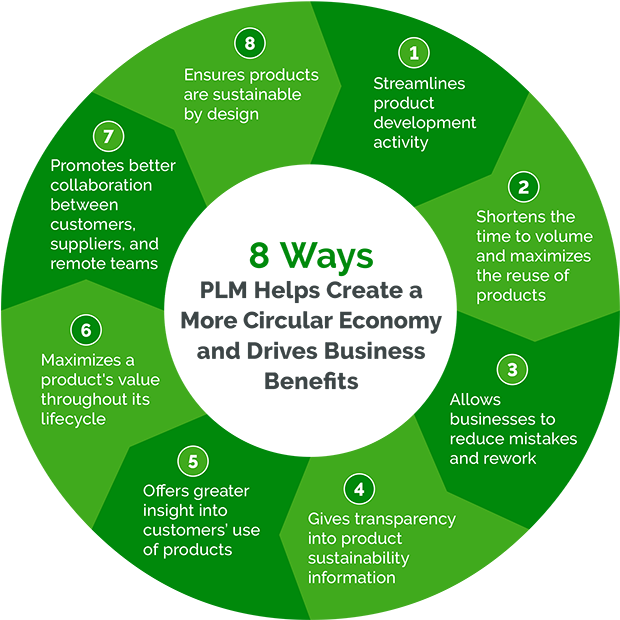

8 Ways PLM Helps Create a More Circular Economy and Drives Business Benefits:

Improves product development activity by streamlining processes, reducing scrap and rework, improving innovation, and reducing time-to-market for new products.

Improves product development activity by streamlining processes, reducing scrap and rework, improving innovation, and reducing time-to-market for new products.- Shortens the time to volume and maximizes the reuse of products by enabling collaboration between design and supply chain teams.

- Allows businesses to reduce product-related costs and waste by focusing on part reuse. PLM can help to avoid sourcing new parts that are functionally similar to other parts already in inventory.

- Gives transparency about what is happening across products and teams.

- Offers greater insight into customers’ use of products through direct access to customer feedback.

- Maximizes a product’s value throughout its lifecycle. By adjusting various strategies as the product progresses through its lifecycle (using data/information based on customer feedback about product performance as it matures), PLM can help extend the product’s lifespan.

- Promotes better collaboration between customers, suppliers, and remote teams. Cloud PLM enables access to product lifecycle information anytime, anywhere, and on any device. Cloud services also deliver quick deployment, unlimited storage capacity, and scalability.

- Ensures products are sustainable by design with visibility to sustainable sourcing information and that no more material than is physically necessary is used to create the best design.4

PLM and circular economy: the way forward

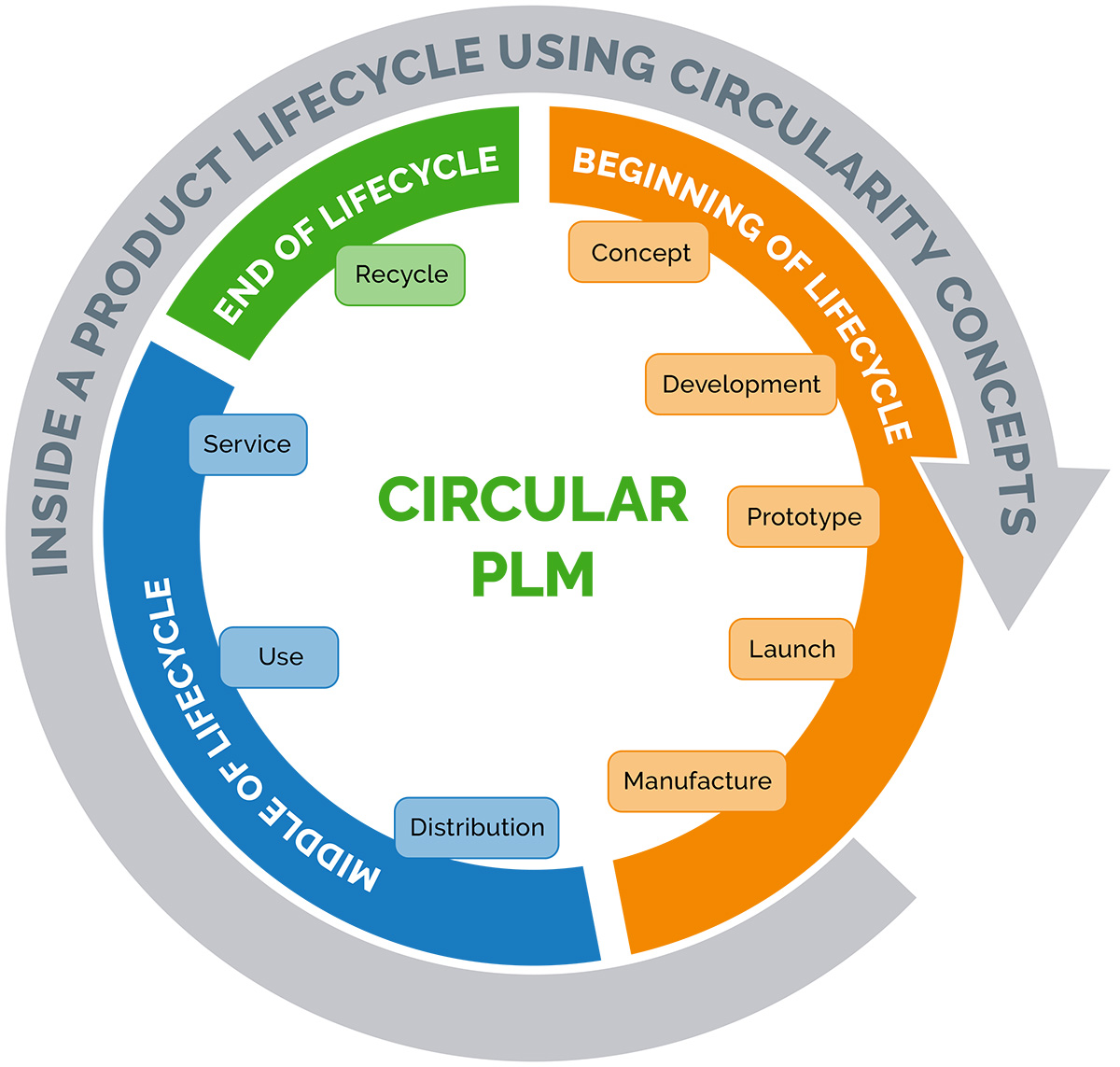

A PLM system is one of the best solutions for companies looking to enhance their product offerings, streamline supply chains, and grow their company. Current Cloud PLM systems are making it easier for companies to enter the circular economy because they cover the entire product lifecycle from creative concept to development—to end of life.

A PLM system is one of the best solutions for companies looking to enhance their product offerings, streamline supply chains, and grow their company. Current Cloud PLM systems are making it easier for companies to enter the circular economy because they cover the entire product lifecycle from creative concept to development—to end of life.

Progressive companies like Trilliant, a leading international provider of solutions for advanced metering infrastructure, smart grid, and smart cities, are taking the initiative to become more circular to reduce their carbon footprint and provide an elevated experience for their customers—PLM is playing a substantial role in their efforts.

Norman Whitehead, Sr. R&D Engineer Technologist at Trilliant stated, “Arena’s Cloud PLM solution helps Trilliant reduce our product’s impact on the environment and achieve a more circular economy. Our partners and employees can collaborate round-the-clock in real time in a centralized system. By tracking and sharing RoHS, WEEE, and REACH compliance information with our supply chain partners, we’re able to address sustainability requirements earlier in our design phases, keep everyone on the same page, and develop greener, more sustainable products faster even though our product complexity is growing.”

PLM software streamlines processes by integrating information, workflows, and systems across a network of cross-functional teams, third-party stakeholders, and geographically dispersed personnel. Using modern PLM solutions companies can easily integrate important sustainability elements like repair or recycling into their products.

PLM also contributes to a reduction in a company’s overall carbon impact. Whitehead further stated, “Arena enables us to better manage and meet environmental compliance requirements by connecting all our stakeholders, supply chain / PLM integration, and cross-functional team members simultaneously. This reduces mistakes and rejects. It also increases our production efficiency while providing lighter and more reliable products. Ultimately, we’re able to provide a more sustainable, less intrusive footprint on the environment and gain a competitive advantage in the smart grid, smart cities industry.’’

Transition from a linear to a circular economy with PLM

The rapid adoption of a more circular economy, which promotes recycling, redesigning, reusing, repairing, and remanufacturing at every stage of the value chain, has the potential to significantly decrease resource consumption. Businesses have a genuine chance to lower costs, strengthen supply chains, adhere to new regulations, and satisfy investor and customer demands by integrating PLM software into their business model.

As more companies begin to transition to a circular model using PLM, they will be able to manage the entire product development process and consider how products can be repurposed once they reach end of life. Companies with a full understanding of the materials that can be reused will be able to make better decisions at an early stage of the design process and develop more sustainable products from the start.

Sources cited

- Circular Economy Action Plan https://environment.ec.europa.eu/strategy/circular-economy-action-plan_en

- Six Simple Features of Circular Business Models Explained https://www.bioregional.com/news-and-opinion/six-simple-features-of-circular-economy-business-models-explained

- The Circular Economy and COVID-19 Recovery https://materialeconomics.com/publications/publication/circular-recovery

- PLM Solutions in the Process of Supporting the Implementation and Maintenance of the Circular Economy Concept in Manufacturing Companies https://www.mdpi.com/2071-1050/13/19/10589