5 Ways Manufacturers Can Boost Agility

Adapting to a New Reality

Adapting to a New Reality

Whether it’s a new regulation, part shortage, or a newly released product from a leading competitor—manufacturers must react quickly to stay ahead in today’s volatile market. The COVID-19 pandemic, natural disasters, and other unforeseen events are creating a wave of supply chain shocks across the globe that impact all sectors of the economy. Companies are now having to reinvent their business operations and develop new ways of working to deal with the long-term effects of these disruptions. This involves the adoption of more agile business practices to better navigate future challenges and maintain a competitive edge.

In this article, we highlight the key characteristics of an agile organization and provide five strategies that manufacturers can adopt to increase agility and thrive in today’s new reality.

What Is An Agile Organization?

In the past, one may have viewed “agility” as just a common buzzword that’s bounced around at corporate meetings. However, today agility is proving to be an essential business asset, especially for manufacturers, as they strive to introduce innovative products to customers on schedule.

So exactly what are the characteristics of an agile organization?

An agile organization exhibits the ability to react and adapt quickly, renew itself, and succeed in a rapidly changing, turbulent environment. It makes quick, informed decisions and constantly pivots without losing sight of the customer.

Agile product manufacturers are more inclined to conduct routine risk assessments and implement countermeasures to lessen the impact of sudden supply chain disruptions, compliance issues, and other roadblocks that compromise new product development and introduction (NPDI).

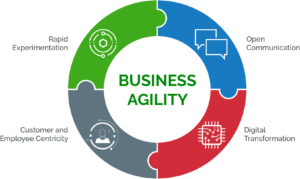

Key Traits of an Agile Organization

Open communication

Agile organizations encourage collaboration and transparency across not only internal teams, but also their external supply chain. Effective supply chain collaboration is critical to ensure quality products are shipped to customers on time. It requires product teams, design partners, suppliers, and contract manufacturers to have access to current product information with the ability for teams to collaborate in real time. This real-time, open communication enables product teams and supply chain partners to stay on the same page when it comes to product design changes. It also enables teams to have greater visibility and react more quickly to manufacturing design issues, material shortages, and other supply chain shocks that impact production.

Adoption of new digital technologies

Rather than sticking to traditional, outdated systems, agile organizations embrace a digital transformation that involves the adoption of new electronic systems or cloud-based technologies to increase operational efficiencies, improve team collaboration, and bring new value to customers.

Customer- and employee-centric business model

Highly successful agile organizations proactively engage customers and empower employees to help drive continuous improvement. Gathering customer feedback enables organizations to gain greater insights into product features and enhancements that create the most value for customers throughout the entire lifecycle. And proactively responding to customer input fosters loyalty that leads to long-lasting customer relationships.

Likewise, encouraging employees across all departments to share their knowledge and identify opportunities for operational improvements and future product innovations empowers them to make changes that benefit customers. It also promotes a culture of accountability and teamwork where everyone works toward a common goal and purpose.

Rapid experimentation

Agile organizations adopt a rapid experimentation and fail-fast mindset to spark continuous innovation and intelligent improvement. With this approach, companies focus on making product changes within rapid iterative cycles. These changes can be analyzed quickly to determine if they are leading to better solutions. Companies can then pursue the changes that have a positive impact and quickly abandon those that are not yielding better results. Regardless of the outcome, this process promotes an environment of continuous improvement and helps drive faster, action-oriented decision-making.

Building The Right Foundation For Business Agility

As you look to improve your current business practices, consider adopting these five strategies to boost agility.

- Identify data silos and communication gaps.

A critical step in building agility is identifying data silos and communication gaps that impede new product development and introduction (NPDI).Key considerations:

- Are your dispersed teams able to collaborate in real time from any location?

- Is it difficult for your teams to keep track of the latest product designs or requirements?

- Does the implementation of changes often lead to confusion or production errors further down the line?

- Do your teams lack visibility into logistics issues, part shortages, and other supply chain risks?

If your product teams and supply chain partners are accustomed to using chat apps, spreadsheets, and other point software solutions, these systems will pose challenges when trying to implement product changes and accelerate time to market. Because these solutions are not connected to the full product record (e.g., bills of materials, supplier lists, requirements, quality records, etc.), it becomes difficult for impacted teams to keep track of the changes that occur throughout new product development. This lack of clarity often leads to errors during the production phase.

Getting all the necessary team members to review, approve, and implement design changes becomes more burdensome and time-consuming when product information is scattered across different locations and systems.

Tracking and managing all the quality processes and records necessary for regulatory compliance can also be daunting when working with manual processes or quality systems that are not connected to the product record. In the event of an unannounced audit, teams are not able to easily identify and compile the necessary quality documentation to demonstrate compliance.

Finally, the inability to collaborate in real time from any location prevents teams from being proactive when responding to issues—ultimately hindering commercialization success.

- Diversify your supply chain.

It is not uncommon for manufacturers to source parts from a single supplier for their finished products. Consolidating all requirements with one supplier enables manufacturers to negotiate lower pricing. It’s also easier to manage performance and obtain higher quality parts when dealing with an individual supplier.Despite these benefits, reliance on a single source poses greater risk in today’s turbulent market. When hit with natural disasters, pandemics, cyberattacks, and other unforeseen events, your sole supplier may not be as reliable due to no fault of their own. These events can delay transportation of raw materials and cause workforce instability, which ultimately impacts your production schedule.

Manufacturers should have multiple approved manufacturers and suppliers to mitigate issues caused by unexpected events. By diversifying your supply chain, you will have multiple options to source critical components or subassemblies when faced with sudden disruptions. In the case of natural disasters and other regional incidents—having multiple suppliers across different geographical locations lessens the impact of closed ports, canceled cargo flights, and other supply chain logistics issues.

- Consider alternatives to just-in-time (JIT) and lean manufacturing practices.

Just-in-time (JIT) and lean have been the preferred manufacturing practices for most companies over the last few decades. With a focus on minimizing waste and reducing inventory costs, these methods involve ordering and receiving materials only as they are needed for production. JIT and lean practices work well if you have a reliable supply chain and accurate demand planning in place. However, they can be disadvantageous if you are confronted with unexpected supply chain shocks, as they leave no inventory to spare.Consider adopting alternative methods like just-in-case (JIC) as part of your supply chain strategy. Unlike JIT which stocks inventory only as it is needed, JIC stocks up inventory ahead of time and minimizes the risk of material shortages when confronted with unforeseen challenges.

- Leverage business analytics.

More and more companies are leveraging cloud solutions and advanced technologies like the Internet of Things (IoT) to gather insights on production processes and product performance. This information enables you to respond to issues more quickly and drive continual improvement throughout the product lifecycle. - Implement a cloud-based product development solution.

Cloud-based product lifecycle management (PLM) and quality management system (QMS) solutions aggregate design files, bills of materials (BOMs), requirements, quality documents, approved supplier/vendor lists (ASLs/AVLs), and other product record essentials in one unified platform.Using a web browser, your dispersed teams and supply chain partners can collaborate anytime and anywhere to quickly create, review, and approve product designs. Because automated processes and revision controls can be applied to parts, BOMs, and documents—you can be confident that your teams are always accessing the latest product information to deliver high-quality products to customers.