5 Tips to Improve Supply Chain Collaboration

The COVID-19 pandemic exposed problems with global manufacturing and supply chains. Shortages in semiconductor chips, steel, and other critical materials have created major delays in getting products to consumers and manufacturing suppliers. These vulnerabilities are prompting many companies to develop more collaborative and resilient supply chain strategies. In this article, we share insights and tips to help you optimize supply chain collaboration and overcome disruptions.

Supply Chain Challenges

As manufacturers look to meet growing customer demands, expand their product portfolio, and enter new markets, it creates a whole new set of challenges for their supply chain.

Whether it’s a particular product configuration or support plan, customers today expect an abundance of options as part of their buying experience. Supply chains are having to embrace new digital technologies and fulfillment practices to accommodate the growing demand for faster delivery times, increased order visibility, and greater product customization. Build-to-order production processes, strategic inventory placement, and last-mile manufacturing are some of the approaches being used to meet these requirements.

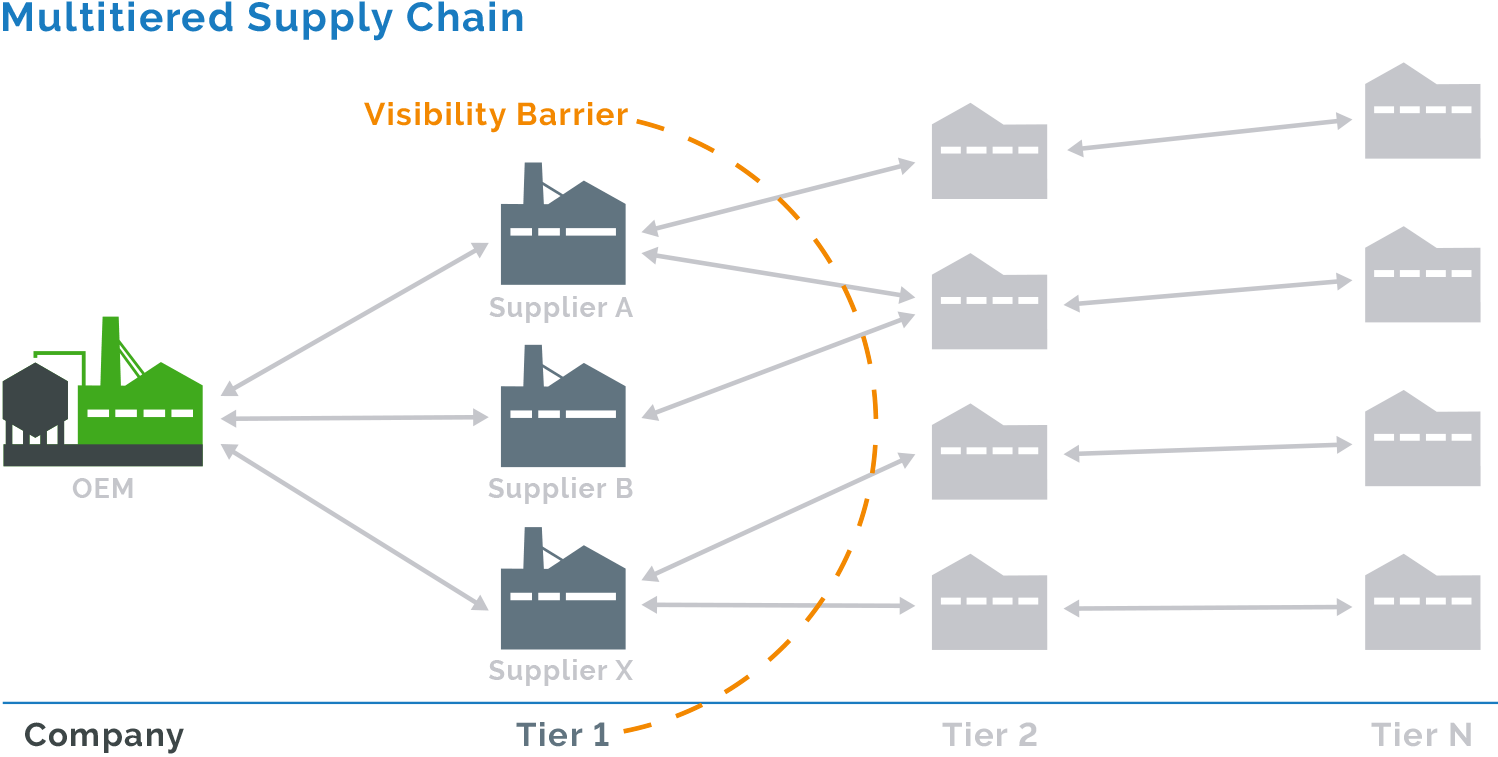

Many manufacturers are targeting new markets and expanding their global footprint to meet growing consumer demand. To support sourcing and order fulfillment on a global scale, they must change how they interact with their suppliers and partners. However, working with more partners and multitiered supply chains makes it difficult to keep everyone on the same page throughout the product development and launch process.

Most original equipment manufacturers (OEMs) communicate primarily with their Tier 1 suppliers and are slow to share information with their lower-tiered partners (e.g., Tier 2, Tier 3, etc.). In turn, some suppliers are hesitant to share proprietary information or quality and compliance issues to avoid risking partnerships with OEMs and other tiered suppliers. This behavior prevents key players from gaining a complete and accurate picture of issues during product planning and volume manufacturing phases. Ultimately, there is limited visibility as supply chains rush to get their products to consumers.

When unforeseen events like the COVID-19 pandemic arise, manufacturers are unable to recognize the early warning signs and respond quickly to changing conditions, part shortages, compliance issues, and other ensuing supply chain shocks. This results in product delivery delays and negatively impacts the manufacturer’s bottom line.

Importance Of Supply Chain Collaboration

Frequent communication is key to ensuring the successful coordination of all supply chain activities and timely delivery of products. According to a McKinsey report, companies that regularly collaborated with suppliers demonstrated higher growth, lower operating costs, and greater profitability than their industry peers1.

The ability of internal product teams and external supply chain partners to regularly collaborate on design changes throughout the new product development (NPD) process ensures both interoperability and manufacturability of the final design and reduces the likelihood of production or quality issues further down the line.

By extending collaboration across all tiers of the supply chain, information can be exchanged more efficiently—resulting in improved component forecasting, shorter lead times, streamlined procurement processes, and increased productivity. As teams begin to share information routinely, manufacturers can gain greater visibility into operational issues and mitigate supply chain risks.

Supply Chain Collaboration Essentials

Making small, incremental changes to how you engage with suppliers goes a long way in helping you establish stability in your manufacturing process and overcome future disruptions.

Here are five tips to help improve collaboration and build more resilience across your supply chain.

- Encourage transparency

From the start, communicate your business goals, performance expectations, and company policies with your supply chain. Your suppliers should have a clear understanding of:- How they should engage with your team and communicate issues

- Your expected turnaround time for a response and/or problem resolution

If you identify the need to find alternate sources for certain parts and services or if you identify quality issues, address it with your supplier. This open and honest dialogue helps build trust and empowers your supply chain partners to be more upfront about issues that arise.

- Be proactive, not reactive

When selecting new suppliers, ensure that their operations align with your business goals and objectives. Key questions to ask:

- Are you able to communicate in real time to your internal and external teams?

- Do you have solid quality assurance and quality control programs?

- Have you implemented a disaster recovery and risk management plan?

Don’t wait for a natural disaster or other major disruption to expose deficiencies in your product launch and supply chain operation. Initiate open discussions with your suppliers to make sure you are both prepared to adapt to unforeseen events.

- Meet regularly with your suppliers and procurement/sourcing team

If you don’t have collaborative tools to communicate effectively, be sure to schedule regular meetings with your supplier and operations team to identify proactive measures should there be issues with sourcing, manufacturing, or shipping.

- Establish and analyze key performance metrics

Work closely with your internal and external stakeholders to establish metrics to monitor production and supply chain performance.Some key metrics to consider include:- Quality and regulatory compliance

- Inventory availability, turnover, and lead time

- Supply chain related costs (e.g., components, subassemblies, sourcing, shipping, etc.)

- On-time shipment of your products

Then, analyze your key performance indicators (KPIs) often and make course corrections before issues become critical.

- Embrace a digital transformation

A key way to enhance communication involves bringing the product data, people, and business processes together into a secure, single source of truth. Advanced digital technologies like cloud software enable controlled, real-time supply chain collaboration—providing both internal and external teams a shared platform to exchange product information. By eliminating data silos and communication gaps, cloud technology improves the flow of information to speed identification and resolution of design or manufacturing issues.Cloud-based product lifecycle management (PLM) and quality management system (QMS) solutions provide a single system for all teams to review, collaborate, and approve the latest design changes anytime and anywhere. Providing immediate access to all things that are product and quality related enables OEMs and suppliers to pivot quickly when faced with disruptions.

Additional Resources

Rethinking the Supply Chain: Staying Connected in Times of Uncertainty

References

- McKinsey & Company. Taking Supplier Collaboration to the Next Level. 2020.