More and more companies are leveraging enterprise application integrations to enhance data exchange and functionality across multiple systems. In turn, they can streamline workflows and increase operational efficiency and scalability. Here, we discuss how integrating product lifecycle management (PLM) software with other enterprise solutions enables manufacturers to better manage the entire new product development and introduction (NPDI) process and accelerate time to market. We also review common integration methods and key business considerations when initiating a PLM integration.

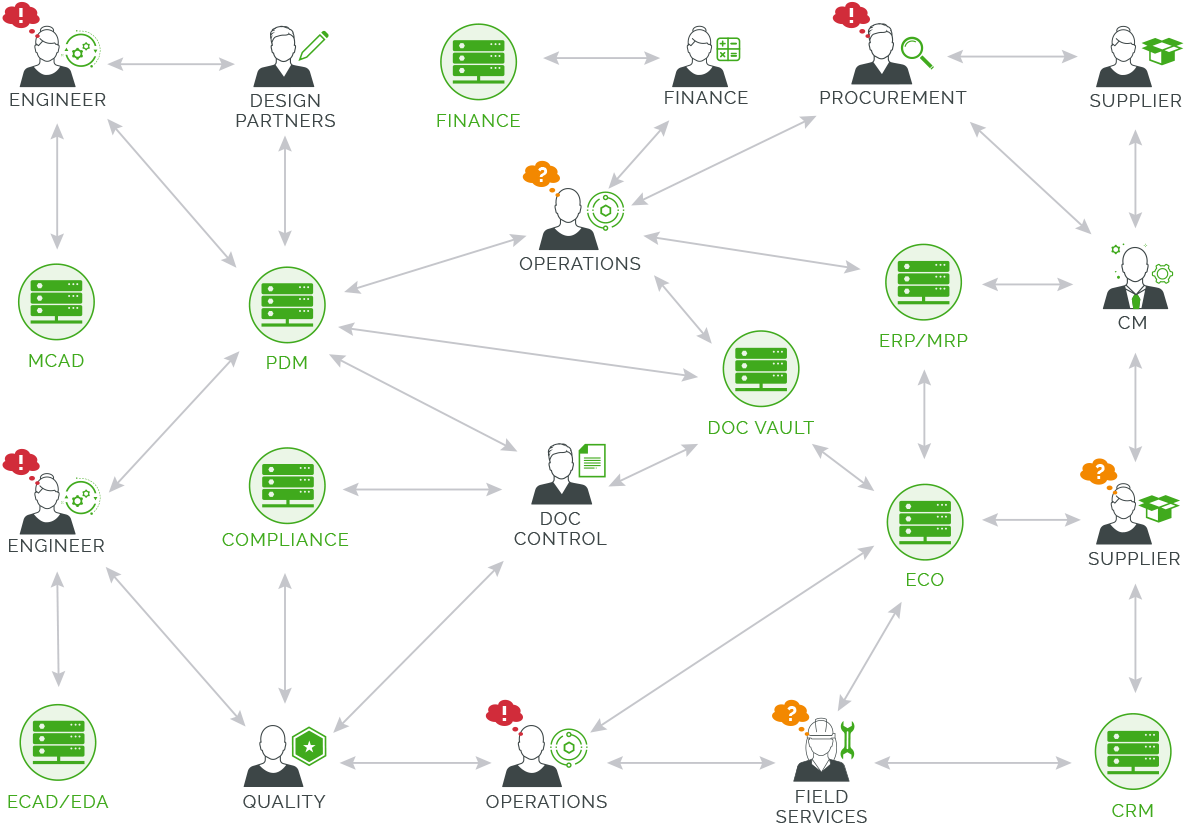

Today’s manufacturing ecosystem consists of a diverse mix of product teams and supply chain partners from across the globe. They often rely on multiple, disjointed software applications to design, develop, and maintain a product. Teams must switch from one system to another and manually re-enter data to keep product information up to date and move processes along. This can be a labor-intensive task that results in errors and costly delays.

Disconnected Systems Result in Errors and Inefficient Workflows

Enterprise PLM solutions serve as the single source of truth for managing the product bill of materials (BOM) and associated quality and change processes. Integrating PLM with upstream and downstream enterprise systems ensures a smooth handoff of product information between design, quality, and production teams. Because data is automatically updated and transmitted across all systems, everyone has full visibility into any changes or issues. Ultimately, they can work more efficiently to get high-quality products to market on time and on budget without any surprises.

Companies that integrate PLM with ERP and other enterprise systems are more likely to realize these benefits:

There are various methods that can be used to connect enterprise systems. Some require minimal IT resources whereas others may involve more extensive coding or customization for deployment.

An API is an intermediary that is used for point-to-point integrations, enabling two different software systems to talk directly to each other and securely exchange data and functionality. Because APIs have a defined architecture and protocol for sharing information, they simplify the integration process. Typically, SaaS PLM vendors will provide customers their own APIs for integration. REST APIs are well-documented, fast, and can be implemented as needed to support greater scalability.

An EDI is a standard electronic format that is used to move business documents from one organization’s computer system to another. It automates and replaces paper-based transactions such as invoices and purchase orders. EDIs can be challenging to implement and maintain due to the unique and ever-changing requirements of each business.

Middleware is software that lies between the applications and their operating system. It functions as a “hidden” translation layer between systems, enabling communication and data management capabilities beyond what is provided in the operating system. This approach is used when more complex business rules are needed, or a large volume of data is transmitted between systems. Middleware requires extensive programming and can be costly to configure and maintain. It does not allow for scalability.

Before integrating your PLM solution with another enterprise system, consider the following:

The enterprise system(s) that you choose to integrate with PLM will depend on your unique business needs. By implementing a proven cloud-native PLM solution, you will have a solid foundation to effectively manage product data throughout the entire lifecycle. Hence, you don’t necessarily need to start with a fully integrated system. Integrating PLM with SCM enhances efficiency, agility, and compliance in product development, driving innovation and responsiveness in competitive markets.

If your engineering teams want to automate the transfer of CAD designs and corresponding files (i.e., parts and assembly drawings) into the PLM system, then you should consider starting with a PLM and CAD integration. Alternately, if you are looking to manage additional business activities such as inventory management, material planning, and order tracking, then start with a PLM and ERP integration.

In any case, work with your PLM software vendor and inquire about their integration capabilities. Determine if they have a marketplace that offers partnership programs, no-code apps, or customized solutions to address your needs. Ultimately, the integration shouldn’t be a time or cost burden to your business. Instead, it should help you scale and reach your product realization goals.