9 PLM Software Essentials to Help Advance Your Business

If your organization is currently using product lifecycle management (PLM) software or considering it for the near term, you’re part of a growing trend that continues to gain momentum across many industries. According to a recent report, the global PLM market size was valued at $26.71 billion in 2020 and is expected to grow at a rate of 6.2% over the next few years1.

If your organization is currently using product lifecycle management (PLM) software or considering it for the near term, you’re part of a growing trend that continues to gain momentum across many industries. According to a recent report, the global PLM market size was valued at $26.71 billion in 2020 and is expected to grow at a rate of 6.2% over the next few years1.

What Is PLM?

PLM is the process of managing all data and processes that are tied to the product record—from concept through design, development, and production. PLM software brings the complete mechanical, electrical, and software design together into a single source of truth and enables product companies and their supply chain partners to streamline product development while driving continuous quality improvement.

What’s Driving the Movement to Adopt PLM Software?

Product manufacturers are facing more obstacles than ever before in today’s ever-changing, competitive market. Economic and political activities across the globe have caused supply chain disruptions that impact the on-time delivery of products. The shift to remote-based work has also created silos among dispersed teams—making it difficult for everyone to stay aligned during the product design and production phases. Moreover, emerging technologies such as the Internet of Things (IoT) and artificial intelligence (AI) have added greater complexity to the product development process.

With the adoption of enterprise PLM software solutions, companies can overcome these challenges and achieve their new product introduction (NPI) goals, while reducing costs. When selecting a PLM solution, it’s important to develop a well-defined implementation strategy and leverage the following software capabilities to achieve optimal results.

PLM Software Essentials for Manufacturers

- Collaboration

A critical function of cloud-based enterprise PLM software is the ability to bring dispersed teams together using a single, unified system. Your internal product teams and supply chain partners should be able to collaborate in real time from any location using a web browser. This eliminates silos and ensures that everyone is always on the same page. - BOM Management

The ability to effectively create, review, and approve the latest bill of materials (BOM) ensures that the right product gets built without mistakes or quality issues. It also ensures that costs are properly allocated throughout the production phase and that product teams have visibility into any changes that may impact sourcing or production further down the line. - Engineering Change Management

Engineering change management provides controlled design change processes that speed product development. Product team members can process formal engineering change requests (ECRs) and engineering change orders (ECOs) more efficiently with automated approval routings. Team members can also document and track all component, assembly, drawing, software, and other changes throughout the entire product lifecycle. - Document Management

To meet the demands of today’s highly regulated environment, you must be able to control, track, and manage all of the documentation associated with product and quality records. This includes product specifications, assembly instructions, standard operating procedures (SOPs), quality policies, and training records. Document management allows for the centralized storage of documentation and the establishment of approval audit trails and streamlined retrieval. - Regulatory Compliance

If your company is subject to export controls, environmental laws, and/or quality compliance regulations, the PLM platform should ensure process, policy, and system adherence. To mitigate compliance risks, it should help your organization adhere to FDA, ISO, RoHS, REACH, ITAR, EAR, and other key industry standards. - Project Management

Project management capabilities allow your product team to keep track of tasks, assignments, and resources throughout the entire product lifecycle and ensure that all product development milestones are met. This helps provide visibility with all affected teams and allows management to make better decisions regarding priorities and product launches. - Business Analytics

The ability to track and analyze metrics provides organizations with greater insights into their product and quality processes to better drive continuous quality improvement. Having access to key performance indicators (KPIs) also helps organizations take a more proactive stance in mitigating risks that may negatively impact new product development and introduction (NPDI). - PLM Integrations

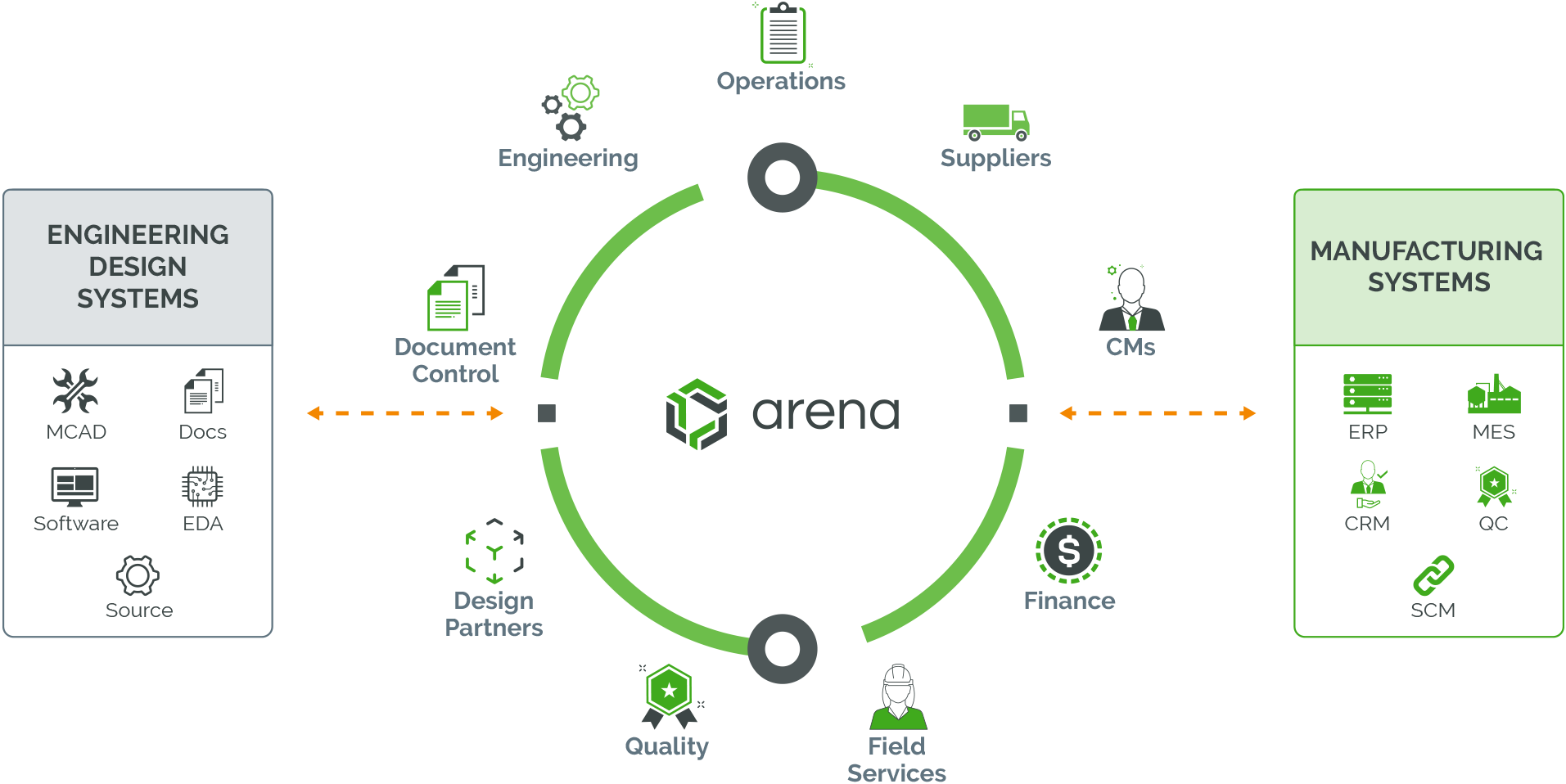

Your organization may already rely on upstream and/or downstream software solutions to help manage the design and production phases during the product lifecycle. By connecting PLM software with these other systems, you can further streamline your product development process and accelerate time to market (TTM).

PLM software should allow for easy integration with these types of systems:

- Enterprise resource planning (ERP) systems

- Engineering design solutions (EDA and MCAD)

- Electronic component databases (e.g., SiliconExpert, Octopart)

- Customer relationship management (CRM) systems

9. Cloud Infrastructure

If you’re looking for a system that enables fast deployment, requires minimal IT infrastructure, and scales with your business needs—then a cloud-based SaaS (software as a service) PLM solution is your best choice.

Unlike traditional on-premises PLM solutions that require costly IT resources and expenditures for hardware, software, virtual private networks (VPNs), and other aspects of deployment—cloud-based platforms relieve the customer of this overhead and allow for delivery of continuous enhancements by the PLM software vendor. This eliminates traditional upgrade costs and ultimately reduces your total cost of ownership (TCO).

Cloud-based SaaS solutions such as Arena PLM drive efficiencies throughout the entire product lifecycle, enabling companies to accelerate the introduction of new, innovative products.

To learn more, read our Ultimate Guide to PLM Software and read the PLM frequently asked questions.

References