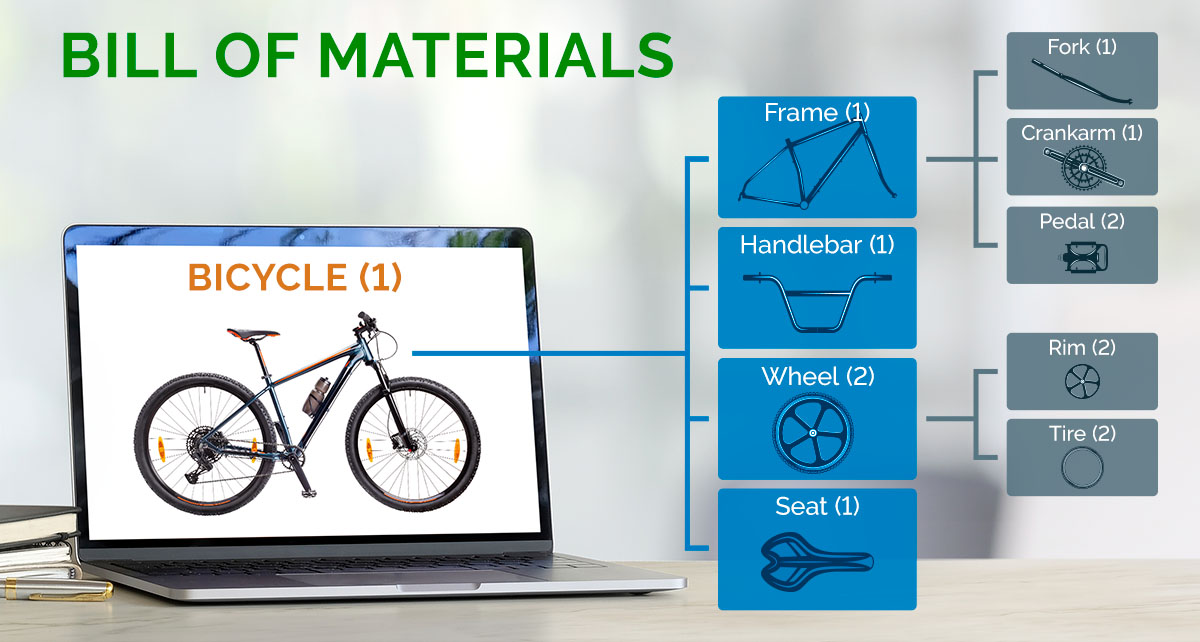

Bill of materials (BOM) management is the process of organizing and controlling all information pertaining to the components, parts, assemblies, subassemblies, and other materials necessary to produce a product.

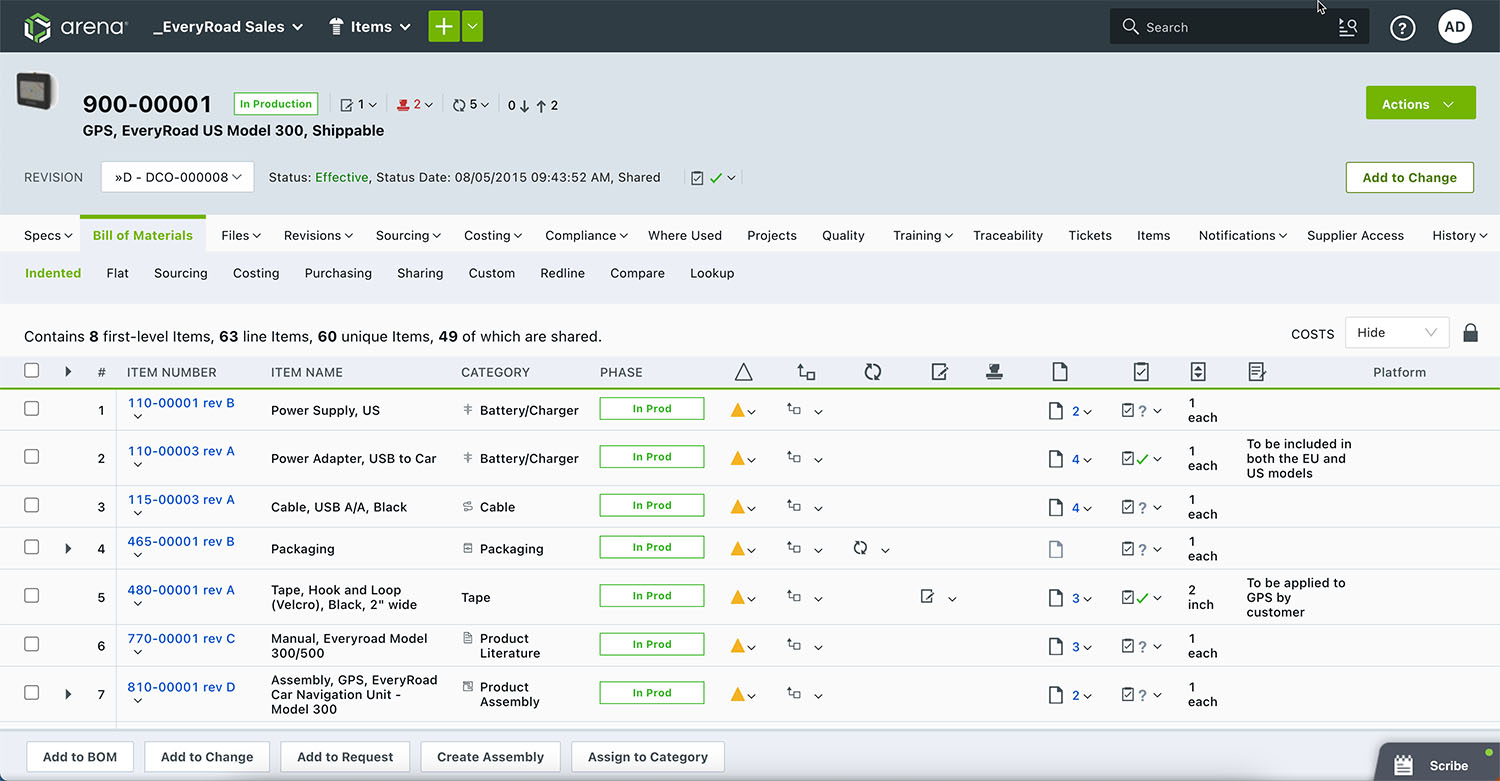

It entails compiling and maintaining a list of all the items required to manufacture a product, including their quantities, costs, and suppliers. This data is essential for production planning, inventory management, and purchasing. BOM management software is commonly used to organize and streamline this process, allowing manufacturers to generate accurate BOMs quickly and efficiently.

Effective BOM management enables manufacturers to reduce errors and waste, ultimately resulting in more cost-effective production processes. In addition, it allows manufacturers to identify and track the availability of all components, enabling them to optimize inventory levels and avoid production delays.

Mismanagement of the Bill of Materials (BOM) can lead to delays and errors in product development. This article highlights the importance of accurate BOM management and the challenges companies face, such as inconsistent data and poor change management. Implementing cloud-based systems, standardizing formats, and automating version control can mitigate these issues. Optimizing BOM processes ensures higher product quality, reduces production delays, and lowers costs, ultimately leading to successful product launches.

Achieving success in Design for Assembly (DFA) hinges on accurate BOM management. Missteps like outdated data and poor version control can disrupt the assembly process, leading to delays and higher costs. This article explores best practices such as using a centralized product lifecycle management (PLM) system and automating change tracking. By streamlining BOM workflows, manufacturers can accelerate assembly, reduce errors, and optimize product quality, driving success in DFA initiatives.

In electronics manufacturing, the Bill of Materials (BOM) plays an essential role in managing every phase of the product lifecycle. This article delves into how integrating the BOM with PLM systems can enhance design accuracy, improve procurement efficiency, and ensure regulatory compliance. By automating component sourcing and incorporating version control, companies can mitigate delays and lower costs, ensuring smoother product development and higher quality outcomes across the lifecycle.

A well-defined bill of materials, or BOM, is essential for accurate and effective manufacturing processes. Mistakes in the BOM can be costly and result in lost time and money, or create a shortage of essential parts.

Read how to avoid five common BOM mistakes to ensure manufacturing success.